Surface treatment

PROCESS

Our surface treatment workshop is specialized in:

- Technical deposits,

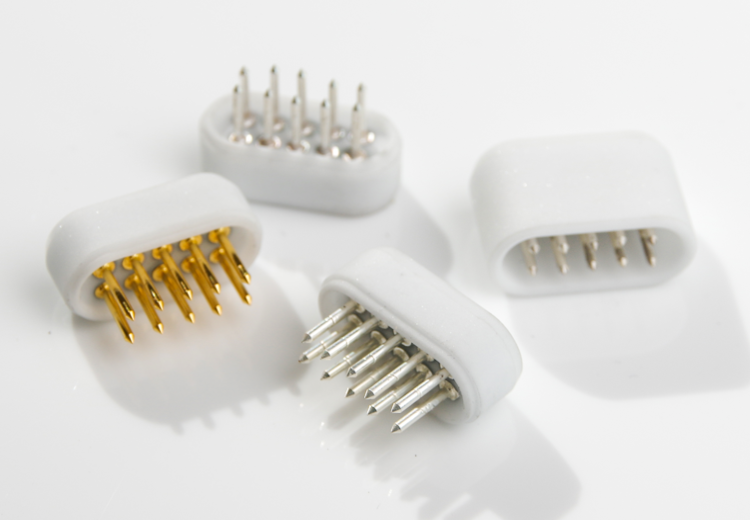

- Deposits on refractory metals (Mo, W)

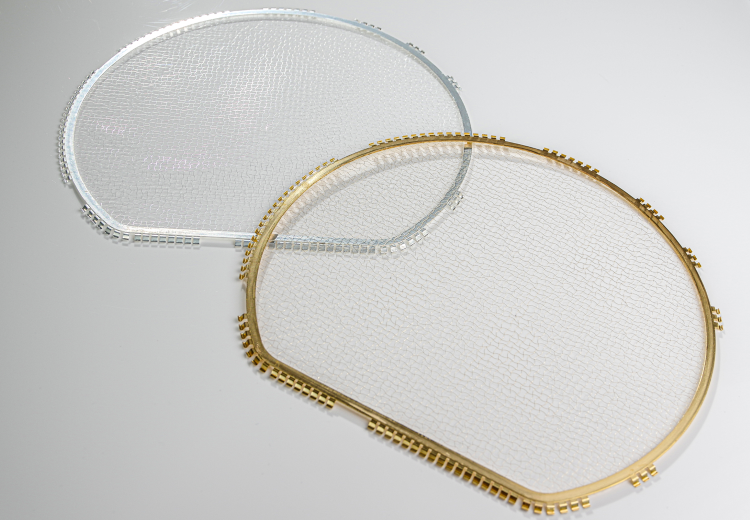

- Localized deposits

- Barrel deposits

- Attachment deposits

Continuous monitoring of baths and operating conditions ensures the quality and reliability of coatings that meet the most stringent specifications.

OFFERED TREATMENTS

|

RESOURCES AND EQUIPMENT

|