Electroforming

Process

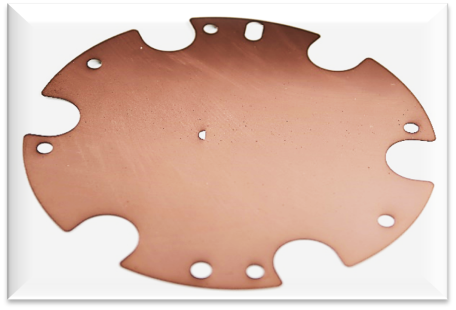

This technique involves depositing a metal layer (nickel, copper, gold, etc.) onto a support, where the desired piece has been previously reproduced photographically or in 3D on a machined chuck.

Once the desired thickness is achieved, the piece is separated from its support.

Through this process, WIPELEC creates very thin parts or parts with extremely fine openings (5 µ).

Advantages

Ability to create openings finer than the material's thickness

- Homogeneous metal structure

- Regular hardness

- Controllable thickness from 4 to 200 µ

- No initiation of rupture

- No sharp edges